The Wartsila-Sulzer RTA96-C turbocharged two-stroke diesel engine is the most powerful and most efficient prime-mover in the world today. The Aioi Works of Japan’s Diesel United, Ltd built the first engines and is where some of these pictures were taken. It is available in 6 through 14 cylinder versions, all are inline engines. These engines were designed primarily for very large container ships. Ship owners like a single engine/single propeller design and the new generation of larger container ships needed a bigger engine to propel them.

The cylinder bore is just under 38″ and the stroke is just over 98″. Each cylinder displaces 111,143 cubic inches (1820 liters) and produces 7780 horsepower. Total displacement comes out to 1,556,002 cubic inches (25,480 liters) for the fourteen cylinder version.

| Some facts on the 14 cylinder version: | ||

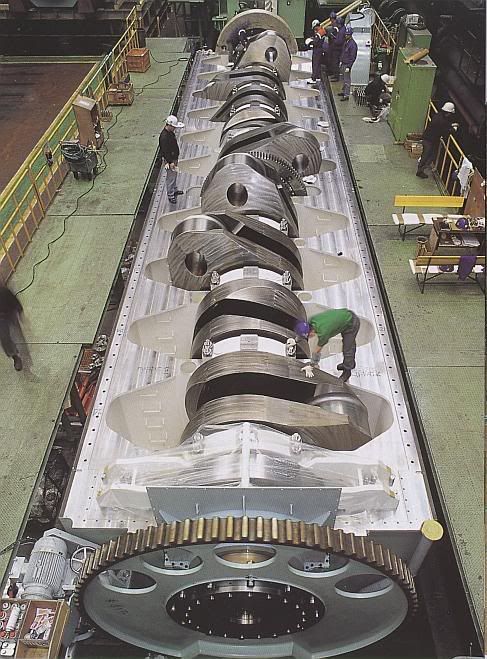

| Total engine weight: | 2300 tons (The crankshaft alone weighs 300 tons.) | |

| Length: | 89 feet | |

| Height: | 44 feet | |

| Maximum power: | 108,920 hp at 102 rpm | |

| Maximum torque: | 5,608,312 lb/ft at 102rpm | |

Fuel consumption at maximum power is 0.278 lbs per hp per hour (Brake Specific Fuel Consumption). Fuel consumption at maximum economy is 0.260 lbs/hp/hour. At maximum economy the engine exceeds 50% thermal efficiency. That is, more than 50% of the energy in the fuel in converted to motion.

For comparison, most automotive and small aircraft engines have BSFC figures in the 0.40-0.60 lbs/hp/hr range and 25-30% thermal efficiency range.

Even at its most efficient power setting, the big 14 consumes 1,660 gallons of heavy fuel oil per hour.

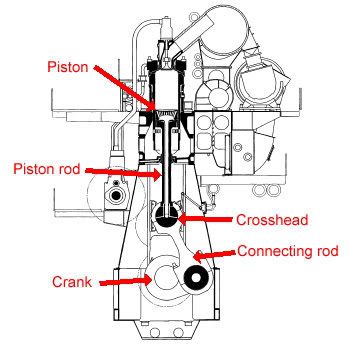

The internals of this engine are a bit different than most automotive engines.

The top of the connecting rod is not attached directly to the piston. The top of the connecting rod attaches to a “crosshead” which rides in guide channels. A long piston rod then connects the crosshead to the piston.

I assume this is done so the the sideways forces produced by the connecting rod are absorbed by the crosshead and not by the piston. Those sideways forces are what makes the cylinders in an auto engine get oval-shaped over time.

Installing the “thin-shell” bearings. Crank & rod journals are 38″ in diameter and 16″ wide:

The crank sitting in the block (also known as a “gondola-style” bedplate). This is a 10 cylinder version.Note the steps by each crank throw that lead down into the crankcase:

A piston & piston rod assembly. The piston is at the top. The large square plate at the bottom is where the whole assembly attaches to the crosshead:

Some pistons:

Some piston rods:

Some piston rods:

The “spikes” on the piston rods are hollow tubes that go into the holes you can see on the bottom of the pistons (left picture) and inject oil into the inside of the piston which keeps the top of the piston from overheating. Some high-performance auto engines have a similar feature where an oil squirter nozzle squirts oil onto the bottom of the piston.

The “spikes” on the piston rods are hollow tubes that go into the holes you can see on the bottom of the pistons (left picture) and inject oil into the inside of the piston which keeps the top of the piston from overheating. Some high-performance auto engines have a similar feature where an oil squirter nozzle squirts oil onto the bottom of the piston.

The cylinder deck (10 cylinder version). Cylinder liners are die-cast ductile cast iron. Look at the size of those head studs!:

A completed 12 cylinder engine:

Worked on both Shulzer and and MAN B&W as a Marine Engineer. MAN B&W makes equally powerfull engines, and are tend to be better in design, from a maintenance point of view.

I supply Wartsila as well as Man B&W seals for these. I’ve never seen what they do, I only hear of it. I’m impressed!

Never seen anything this utterly massive in terms of mechanics.

Very impressive! 😯

How about building time for this?

You’ve actually worked on these? I bet these pictures don’t do it justice in terms of size.

The seals must be massive!

That is a great question, unfortunately I have no idea how long it would take to build one of these.

Can you believe that Wartsila is from Finland. Same country that Nokia came from. Also try to see next time you ride an escalator or elevator look for the brand KONE also a huge Finnish company. I just love this country that is also the least corrupted country. You should visit.

P.S. OHHHH and last but not least, LINUX (sounds of angels singing)

Plz, don’t take the comment above for nothing else than fun facts. 🙄

I wanna see I movie of the 12 cylinder @7200 RPM. With sound please…

What a waist of diesel! With the technology today this is Cave man technology Geez…

Its like a Barel each stroke F- that.. no wonder the Planet wants to exterminate us..

Nice engine i have seen one of those mother f@!k’ers… in real (Ebba Maersk) which also have 5×5500 aux engines for powering the reefers.also seen the spare piston they had on board, not to speak of the cranes needed for maintenance. All in all huge things

Wow! The cylinder deck I thought gave the best example of just how massive this engine is.

just to answer the question above it takes about 4 months to assemble and reassemble the engine. dont know much else just getting started with the company

I want to see the turbochargers! And final compression ratios. I bet theyre not measured in millimeters!

Is it real?? I have never seen nothing like this

What do we replace these with at the end of the “Cheap Oil Era”? I can’t imagine brewing bio-diesel at the rate they drink oil! Will coal and steam come back? Wind was once used, but much lower tonnages and longer times were involved. When these monsters are gone will manufacturing come back to the U.S.A.? Does the end of cheap oil have a golden lining in this respect? The Russians have nuclear powered icebreakers and the U.S. has nuclear powered aircraft carriers, will containerized shipping go nuclear? God help the oceans if nuclear ships go down! We are in for exciting times in the near future aren’t we!

Exactly why I’m glad to be living in this year/time. lol. god help us.

I have never in all my yrs same anything so mindbogglingly. gobsmacking unbelievably fantastic.are the only words i can use for something that is surely beyond anything I have ever seen in all the years on the internet

I think it would be fascinating to see the machines used to make the crankshaft, pistons and connecting rods.